The Importance of Voltage Regulation

15 April 2024

Share this article:

What is Voltage Regulation?

Although the principles of voltage regulation may be inherently complex, the concept at the heart of it is straightforward. You're talking about the ability of any electrical system to provide the constant (or near constant) voltage necessary to successfully and safely operate in a wide range of load conditions.

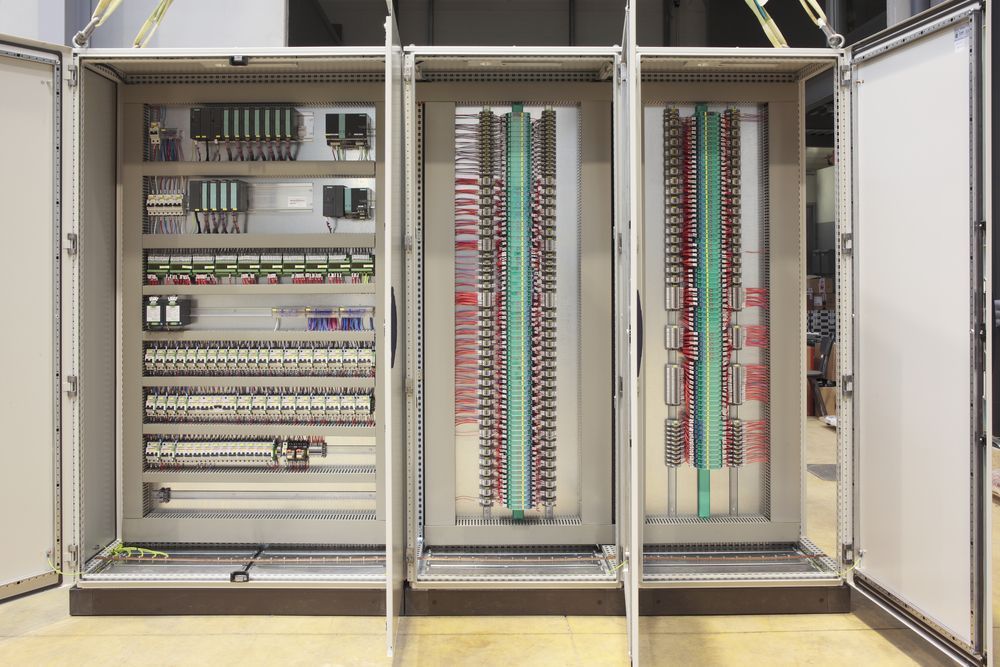

Voltage Regulators

A voltage regulator is a circuit that both generates and manages a secure, fixed output of voltage in whatever power system it is installed in. Essentially, it's making sure that the voltage coming from the power supply is always in whatever range necessary to be compatible with other components.

To that end, there are a few different types of voltage regulators to concern yourself with. One of these is called a linear voltage regulator, which is commonly used in many commercial devices in particular. It employs a "series pass transistor" to make sure that the output voltage stays consistent. It is simple, has low output noise, and offers excellent line regulation. It does have a limited voltage range, however, making it unacceptable for certain types of applications.

Another type is called a switching voltage regulator, which is inherently more complicated but highly efficient. These types of regulators can sometimes cause electromagnetic interference, however, so you must also be careful when using them.

Finally, there is a shunt voltage regulator, which controls the output voltage via a low-resistance path for excess current to bypass the load. It's simple and highly precise, but has limited load current handling.

Typically, the end application will dictate which type of voltage regulator should be used.

Factors Affecting Voltage Regulation

The number one factor that affects voltage regulation is the variation of the load in question. If that load is increased, it will sometimes cause a voltage drop. This refers to the amount of voltage loss that occurs as a result of resistance. That voltage regulator will then need to make up the difference to preserve the safe operation of not only the electrical system but whatever component it is connected to.

There are other factors that affect voltage regulation as well, with temperature being chief among them. If a voltage regulator is suddenly subject to extreme conditions like intense heat, it could change properties like line resistance. This would change how hard the voltage regulator had to work to maintain that consistent voltage, or if it was even able to do so at all.

Obviously, the tolerances of any component attached to the system would also impact voltage regulation. The tighter the tolerances, the more effective the voltage regulator will be at performing its primary function.

As is true with other types of mechanical components, wear-and-tear and maintenance (or a lack thereof) can also impact voltage regulation. As a voltage regulator ages after periods of heavy use, it will naturally become less effective. Its performance may suffer and its ability to accurately regulate voltage may be negatively impacted. At that point, it would either need to be repaired or fully replaced depending on the specifics of the situation.

Why is Voltage Regulation Important?

- Ensures Equipment Safety. Proper voltage regulation always helps to minimize the possibility of dangerous conditions like an arc flash. This can cause not only severe burns to anyone in the immediate area, but long-term injuries and even fatalities due to a catastrophe like a fire as well.

- Improves Productivity & Efficiency. Without proper voltage regulation, you're likely looking at a lot of equipment and systems that malfunction in unpredictable ways. This leads to unplanned downtime, which isn't just frustrating - it's also massively expensive. Voltage regulation keeps power systems running as consistently and as efficiently as possible, meaning that your workers are spending less time dealing with issues and more time being productive.

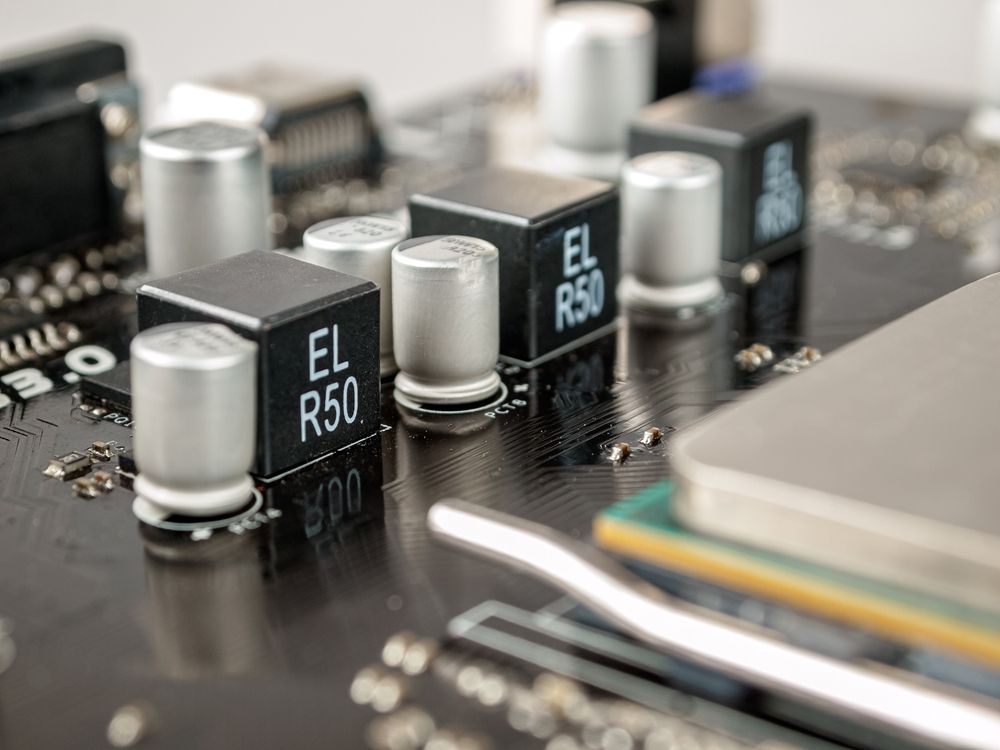

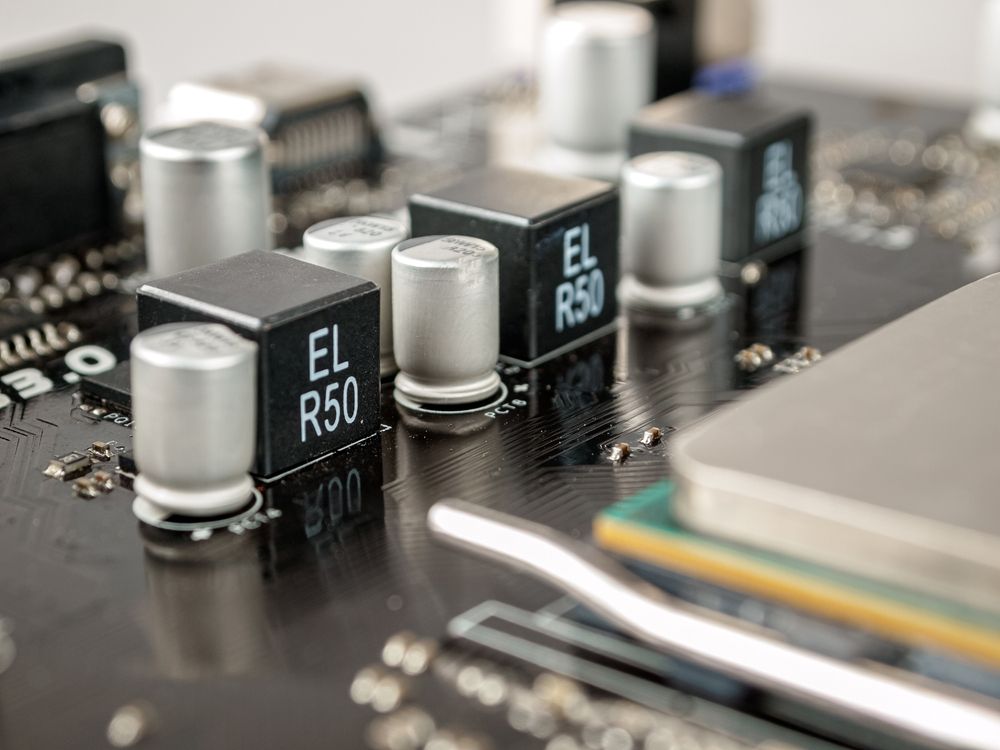

- Prevents Damage to Electronics. Another core reason why voltage regulation is so important is because it helps to prevent damage to mission-critical equipment and other components. Proper voltage levels help prevent thermal stress, which reduces the risk of a failure. It also helps to maximize the lifespan of your equipment as well, all while cutting down on unnecessary maintenance costs.

- Enhances System Reliability. Equipment that constantly cycles on and off due to inconsistent loads goes through an incredible amount of unnecessary stress over time. This requires downtime for maintenance that, even if it is planned, is still costly. It also reduces the lifespan of the equipment as well. Voltage regulation helps enhance system reliability in a way that prevents all this from happening.

- Prevents Data Corruption. Voltage irregularities can lead to sudden system shutdowns, which can lead to corrupt and otherwise lost data. Proper voltage regulation helps make sure this isn't something that you or your own customers have to spend time worrying about.

FGC Industrial Voltage Regulation & Correction Systems

As a division of FGC Equipment, Voltage Correction is proud to offer a wide range of industrial voltage regulation and correction systems for you to choose from depending on your needs. Since 2008, we've proudly offered high-quality solutions to clients in just about every industry you can think of, from industrial organizations to 3D printing facilities to those in oil and gas, mining, commercial/retail, emergency lighting, and more.

In addition to our 24/7/365 emergency service response capabilities, clients have also come to trust us over the years thanks to our robust preventative maintenance plans. We can keep all your systems free from downtime so that you can focus all your attention on running the most successful business you can. Also available is our FGC Asset Management software, which allows you to log all historical maintenance and repair data in one easy-to-manage location. You can also view your current calendar of maintenance activities, dive deep into information pertaining to budgeting, and more - all to give you complete control over the asset lifecycle for critical components like voltage regulation and correction systems.

If you'd like to find out more information about the importance of voltage regulation, or if you'd just like to discuss your own needs with

a team of professionals in a bit more detail, please don't delay - contact Voltage Correction today and

request a quote.

Connect with Us: