Medium Voltage UPS Systems in High Density AI Data Centers

20 February 2025

Share this article:

High Density AI compute performance chips like Nvidia Geoforce and now Blackwell B200 chips are requiring up to 300 watt, 400 watt, and 1200 watts. New rounds of chip development are considering up to 3000 watts of power per chip and requiring MEP Engineering design to consider bringing higher voltage closer to the Rack Loads.

Why Medium Voltage UPS Systems

Higher voltage carried over distances is more efficient than lower voltages carried over the same distance. Medium Voltage (13.8kV, 34.5kV) requires lower current (amps) to achieve the same capacities as low voltage (480v/208v), which exponentially changes the amount of power you can move from Point A to Point B, point B being the Rack loads.

480V Power Distribution for Data Centers

In a legacy data center, medium voltage would be delivered to a substation or switchboard on-site. Transformers then step down medium voltage to 480V, which is widely used in data centers for the last 35 years.

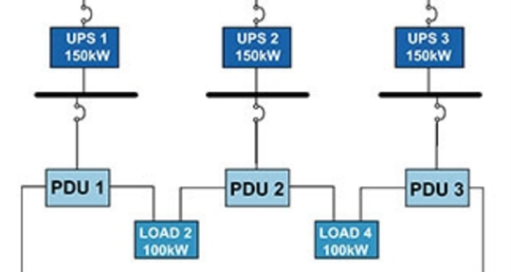

The typical legacy larger data center delivers 480 volts through the input switchgear, Uninterruptible Power System (UPS) via it’s Maintenance Bypass Switchboard route, and on to a Floor Power Distribution Unit (PDU). At the PDU, the load is stepped down via a internal PDU Transformer to usable 120/208V and 120/240V, which panels of breakers, or sub-feed breakers on the PDU support the actual breakers for servers. Low Voltage UPS Systems are limited to certain capacities to accumulate kW output for larger 2500kW or 5000kVA capacities.

See Diagram 1.1

Medium Voltage UPS Systems in High Density Data Halls

For new high density Rack layouts of 100kW – 300kW per rack load, the most efficient way to deliver the smallest wire, highest voltage, and most capacity closest to the load is to deliver medium voltage directly to the PDU at the rack row. Major issue, most OEM’s have been set up to build most all capacity of Uninterruptible Power Systems in the 480 Voltage.

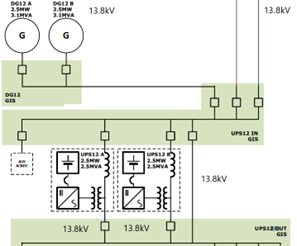

Medium Voltage UPS Systems are now being made available to New High Density Data Centers. In much the same routing of power from Utility, Substation, Switchgear, UPS Gear, and ultimately to a Medium Voltage Power Distribution Unit (PDU) neat the high-density rack loads. 13.8kV or 34.5kV delivered closer to the loads provides major benefits to large megawatt installations.

See Diagram 1.2

Benefits of Medium Voltage UPS Systems

-Higher Voltage at Longer Distances = Efficient Power flow and less effective power loss in amperage. (More Real Current (kw) Delivered to Loads)

-Medium Voltage vs Low Voltage uses smaller wire sizes and less connections points resulting in lower material costs per kW during installation. (Less Pipe and Wire)

-Medium Voltage vs Low Voltage uses less connection points resulting in lower Labor Costs per kW during equipment installation. (Lower Installation Labor Hours)

-Medium Voltage UPS Systems provide higher kW capacity in a smaller footprint over legacy 480V low voltage designs. (Higher kW Density psf)

-Installing less components in the delivery line to rack loads lowers total Facility Points of Failure (Less Single Points of Failure)

As an overall guide, you can pack more kW into a smaller footprint using Medium Voltage UPS Systems in your high density Data Hall Design. Using the same concepts of High Density chip computing and direct to chip cooling, bringing more directed high capacity kW power to Rack Loads achieves an increased kW per PSF design, and a lower cost per kW ownership.

See your Voltage Correction Specialist to discuss Medium Voltage UPS Systems and Power Distribution Options. https://www.voltagecorrection.com/medium-voltage-ups-systems

Connect with Us: