Power Outage Protection

Voltage Regulation Solutions. Delivered.

Many utility customers experience both voltage sags and also occasional short term loss of power. These momentary outages or short term loss of power may occur if utility reclosers operate in order to try to isolate faults on the line and to protect the balance of the utility network. Such recloser events are more frequent during stormy weather when high winds may cause tree branches to touch power lines but can also occur if birds or animals stray too close to transformer terminals or bridge across power lines.

90% of Industry power problems are short term in nature. Most are due to sags either internally derived out externally created. Cumulative effects of customers on the Utility Power Transmission create low voltage sagging scenarios throughout the electrical power grid. These sags are the number one culprit affecting industrial operational loads. Visible or not, they are having a daily effect on your equipment and operations.

When you install equipment that will correct power and hold voltage within your facility, you will be providing your facility with protection against all outside influences of power. Avoid wear and tear on equipment within the facility by having stable voltage and power factor. You will lower operational and maintenance costs by limiting voltage and amperage anomalies inside the facility

Flickering of voltage, lights, can mostly be derived internally from a facility. The reaction to changing loads inside a facility or complex is an ever changing dynamic. Especially with industry which is producing products, manufacturing, or processing. Taxing loads on the utility grids in the summer can create rolling sags or brownouts. These sags on the voltage will dip so far that lights will flicker or flash out.

Short and long term power disruptions can cause continuous production losses for customers. Sensitive electronic circuits can be permanently damaged, electrical and mechanical systems are effected and the overall costs of these events can be significant. Not to mention the downtime effects of a long term power event. ICP has Solutions for short and long term power events.

Cost of Utility Outages

There are many immediate as well as residual effects of outages which effect equipment and operational costs.

Process downtime, wearing out of controls equipment, and replacement parts cost are a few to mention.

Undertanding those hidden costs that enter your operational budgets doesn’t always show up as the result of an outage or power sag.

But many are the result of them.

Most customers that call the Electric Utility Company that are experiencing events do not get any specific helpful information because all the events are happening past the Utility distribution point.

Voltage Regulation Solutions

At Voltage Correction, we offer advanced solutions tailored to industrial environments to protect your systems from power surges, sags, and outages. Our equipment is designed to stabilize voltage and ensure consistent power supply, helping safeguard critical machinery and systems. Voltage conditioners actively monitor and adjust voltage levels, correcting under- or over-voltage conditions to protect sensitive controls and heavy equipment. For continuous protection, voltage regulators maintain stable voltage levels, preventing damaging spikes and surges. With our high-performance solutions, you can reduce downtime, avoid costly repairs, and ensure smooth, uninterrupted operations in your facility.

90% of power related problems for industry are sag related, not outages.

Contact a Voltage Correction consultant today to discuss power correction options for your facility. Leasing options available that match cost of owning one to one with cost/efficiency savings.

Why Doesn’t the Power Utility Company understand my power issues?

Many utility customers experience both voltage sags and also occasional short term loss of power. These momentary outages or short term loss of power may occur if utility reclosers operate in order to try to isolate faults on the line and to protect the balance of the utility network. Such recloser events are more frequent during stormy weather when high winds may cause tree branches to touch power lines but can also occur if birds or animals stray too close to transformer terminals or bridge across power lines.

The Electric Utility Company measures its voltage and quality of power at the distribution point. It does not follow downstream to transformer distribution, or to the distribution points local to the customer. Most customers that call the Electric Utility Company that are experiencing events do not get any specific helpful information because all the events are happening past the Utility distribution point. The Utility Power Industry is also federally regulated. Therefore they are unable to provide any solution referrals to the problem. Their information only shows good power being made at the distribution point which frustrates the customer as it is impossible for them to help. Almost all of these customer instances can be corrected locally with a Voltage Correction Device or Industrial UPS System and should not rely on the transmission distribution to get better.

If the Utility Company isn’t Causing Power Sags, Surges, and Outages What is?

It is certainly possible and likely that power issues are derived internally downstream from the utility service entrance. Facility equipment cycling on and off will pull on various phases. It is never constant and voltage is always changing inside a facility if there are any sorts of dynamic loads. Most sags or surges you will not see with your naked eye. Most events are undetectable to the naked eye. If you see light flickering, that is 100% fluctuations in voltage and causing different variances in the amperage to all your loads. Therefore you feel as if power is OK, in reality, equipment is being damaged and worn. Best way to find out is a meter and power study.

Have a site survey done to survey your facility and install a power metering device.

When you install equipment that will correct power and hold voltage within your facility, you will be providing your facility with protection against all outside influences of power. Halting wear and tear on other equipment in the facility by having stable voltage and power factor is the goal. The long term positives are lowered operations and maintenance costs by limiting voltage and amperage anomalies inside the facility. It is common to vet these issues by installing a monitoring device at the service entrance of the facility utility power. This is a low-cost method to really understand these issues and to make a proper diagnosis.

We are available to review electrical one-lines, Power Reports, Demand Usage, and any other data on your facility power.

Contact your Voltage Correction Technical Representative today to discuss options to increase efficiency in your facility and correct our facility power issues!

RFP Initial CTA Homepage

We will get back to you as soon as possible.

Please try again later.

WHY CHOOSE FGC?

The Customer Experience

FGC Asset Management Software - Asset / Portfolio Tracking

Roll all your Critical Assets and Maintenance Programs into one location - Facility Keys Preferred Platform

Log historical maintenance and repair data, view current calendar of maintenance activities, manage and control Asset Lifecycle. Budgeting, Billing, Reporting all in one easy location.

7 x 24 FGC Emergency Service Response

24x7 emergency service Services through FGC Services and Response Platform, 7x24 NOC.

Preventative Maintenance Plans Provided by FGC Services

Keep all your systems free of downtime with Preventative Maintenance Programs.

Plans include Full Service, Preventative Maintenance Plus Emergency Response, and PM Only.

Parts coverage inside your warranty period, extended plans available for Annual or Multi-Year Programs

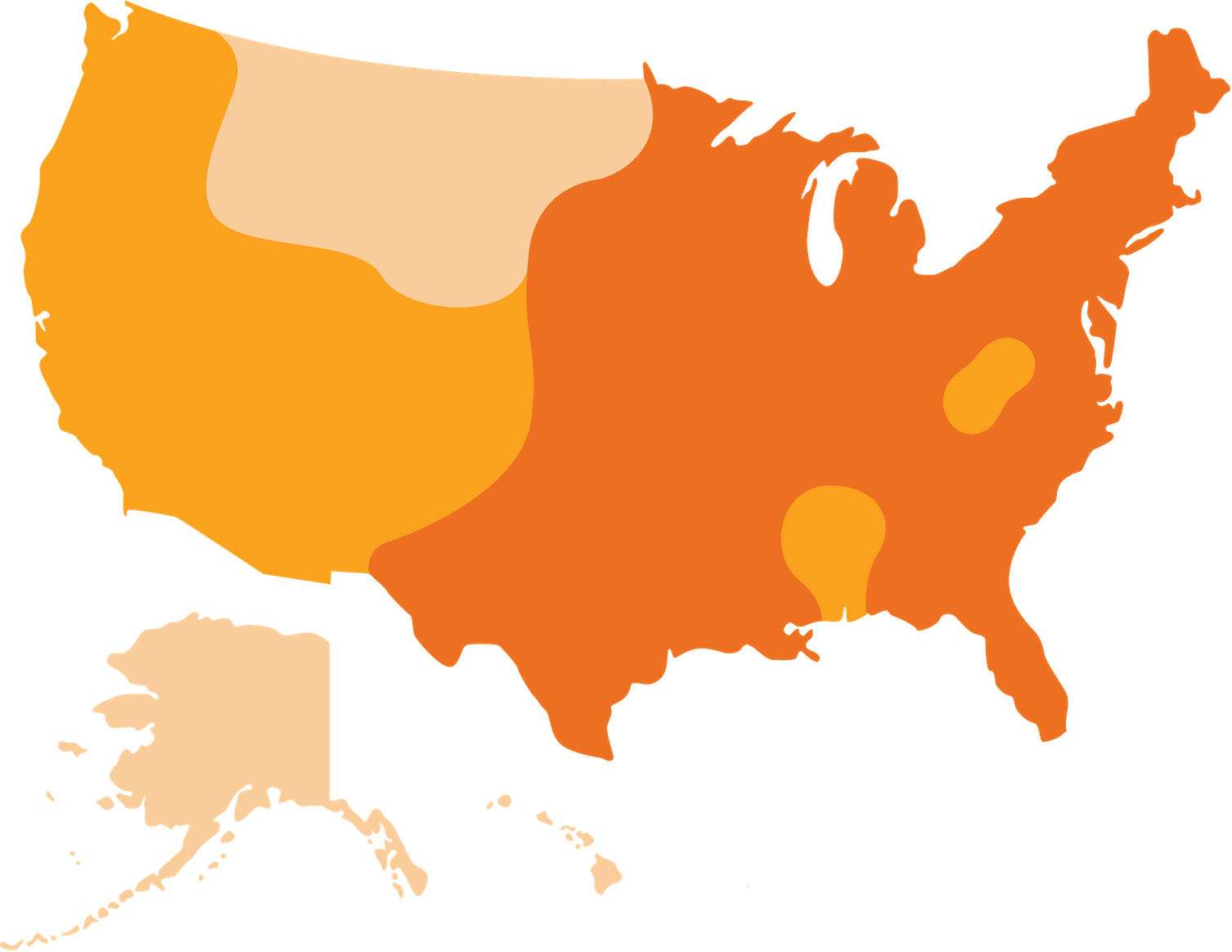

FGC Comprehensive Services - Your Partner in Business

FGC is a 20 Year Nationally Recognized Distributor and Service Provider for Critical UPS Systems, and Battery Services. National Equipment Sales coverage in the Continental US States, National Service Coverage in the Continental US States. Your trusted Partner for all Critical Equipment, Technical Services, or Installation needs.

FGC 7x24 Emergency Response / Repair UPS

FGC National Service Coverage for Emergency Calls, On-Site Response, and Remediation.

ADDITIONAL FGC SERVICES

The Harsh environment in a plant facility requires a robust Industrial UPS solution or (AVC) Active Voltage Correction Device.

Contact Us

We Can Help Answer Any Unanswered Questions

Experienced Product Representatives are on hand to send you information and quotations for equipment. If you need help with sizing, installation planning, or general questions about products, please fill in the appropriate form below and someone will contact you shortly.

You may also call 844-501-1887 to get a direct product representative. Or you may chat with one of our product specialists in the chat box provided.

Homepage Footer Contact Form

We will get back to you as soon as possible.

Please try again later.